사례 연구: 탁월한 세대를위한 우수성을 제공합니다 - 카타르

고객: 놀라운 세대, 카타르 프로젝트: 생산 100 알루미늄 합금 축구 트로피

초기 도전: 품질 & 디자인 결함

MC Art Awards는 의뢰되었습니다 놀라운 카타르 세대, 생산합니다 100 나무 기지가있는 알루미늄 합금 축구 트로피. 우리의 고객은 이전에 다른 공급 업체로부터 이러한 트로피를 배치했습니다. 2024, 그러나 상당한 품질 문제가 발생했습니다.

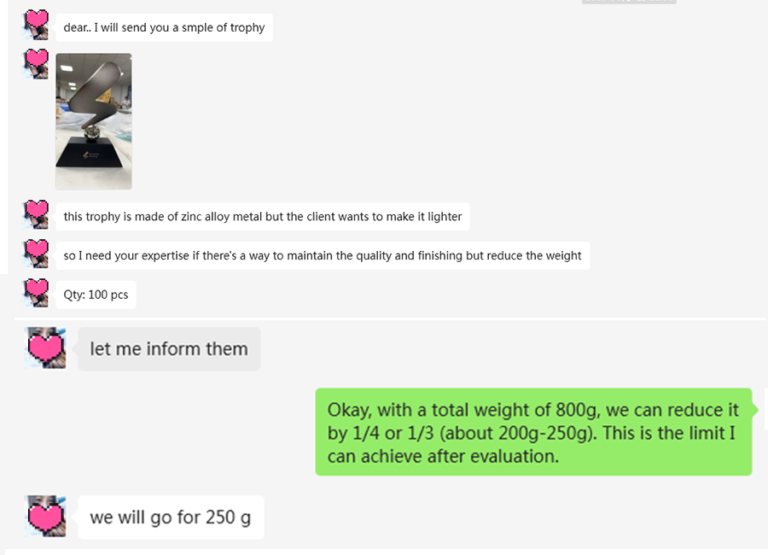

원래 디자인, 세 가지 개별 구성 요소로 구성됩니다, 3 개의 나사에만 의존하는 방법을 사용하여 조립되었습니다.. 이 접근법, likely chosen by the previous supplier for its simplicity and cost-effectiveness over a more challenging integrated screw design, unfortunately led to instability and deformation of the trophy. Furthermore, each trophy weighed a substantial 800 grams, exceeding the client’s desired weight.

Generation Amazing tasked MC ART AWARDS with a multi-faceted challenge: to re-engineer the trophy for integrated stability, reduce the weight by 250 grams per unit, and maintain a per-unit cost under $50 USD, all while preserving the original aesthetic design and dimensions.

Our Innovative Solution: Engineering for Excellence

Upon receiving this request, 에반, our Product Manager at MC ART AWARDS, collaborated closely with our product design department. Their mandate was clear: develop a new assembly solution that would achieve integrated fixation and a significant weight reduction without altering the trophy’s external appearance or dimensions.

Through dedicated coordination and innovative problem-solving between our design and production teams, a successful manufacturing plan was devised. We not only met but exceeded the client’s expectations, successfully producing all 100 trophies with the required specifications. The entire process, from initial design conceptualization to client order and final production, was completed within an impressive 15-day timeframe.

overcoming Supply Chain Obstacles: A Commitment to Integrity

The project presented an additional layer of complexity when the client requested customized packaging. The packaging boxes required a metal logo badge, a high-density fiberboard (MDF) core wrapped in black leather, and an EVA foam insert for secure trophy placement. As MC ART AWARDS does not specialize in packaging production, we sought an external partner.

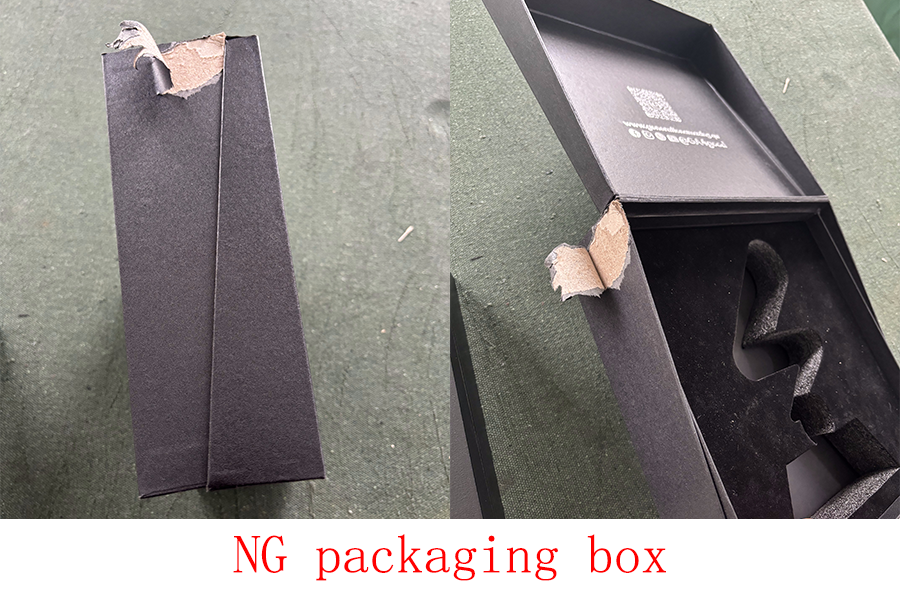

Unfortunately, our initial packaging supplier failed to meet the agreed-upon 15-day deadline. More critically, they unilaterally deviated from the specifications, using cardboard instead of MDF and leather, and employing hot stamping instead of a metal logo badge. This resulted in packaging that was entirely unsuitable and unacceptable.

Recognizing our commitment to a 25-day total delivery promise to Generation Amazing, we immediately sought an alternative. We swiftly engaged a nearby packaging factory, offering double the standard price to expedite production within a strict five-day window. To ensure quality and adherence to specifications, we assigned a dedicated team member to supervise the production process on-site.

This proactive intervention allowed us to successfully complete the packaging and prepare the trophies for shipment from Shenzhen Port to the client’s office in Doha, 카타르, within the stipulated timeframe. While this unforeseen setback resulted in a $1,000 USD loss on the order, we firmly believe that upholding our commitment to the client was paramount. This experience reinforced our core belief that integrity and reliability are the cornerstones of long-term success.

Project Results: Delivering on Our Promise

Successfully re-engineered and produced 100 integrated, lighter trophies.

Achieved a 250-gram weight reduction per trophy while maintaining original design.

Controlled per-unit cost within the client’s $50 USD budget.

Completed trophy design and production within 15 날.

정시 배송을 보장하기 위해 중요한 포장 공급망 문제를 극복.

예기치 않은 도전에도 불구하고 고객 신뢰와 헌신을 유지했습니다.