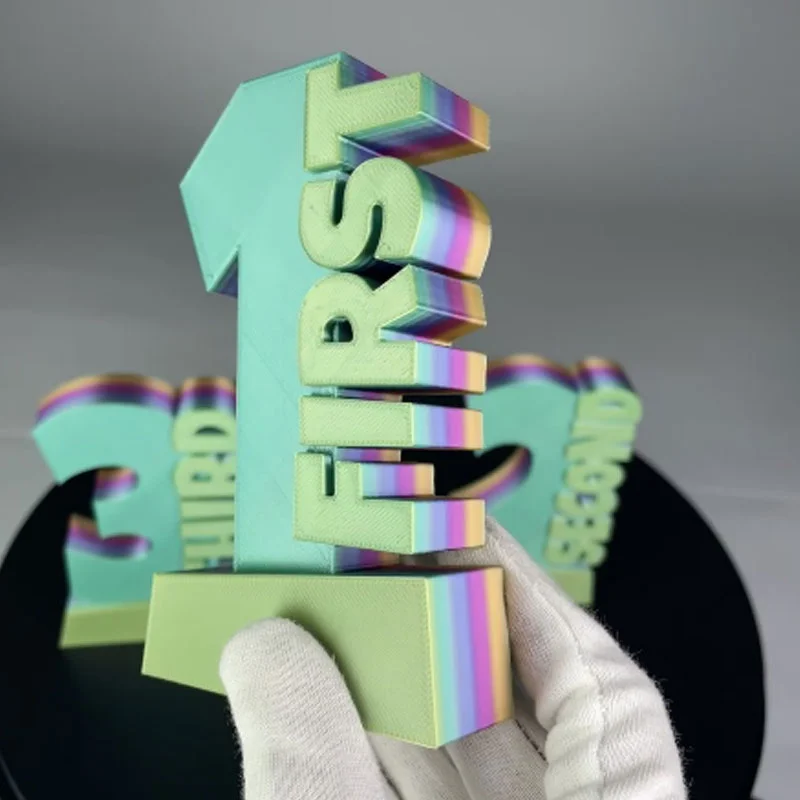

Here are the key scenarios where 3D printed trophies are an excellent choice, helping you make a more informed decision for your next order.

1. For Highly Customized Single or Small-Batch Orders

Traditional trophy manufacturing often requires an expensive mold-making process. If you only need one or a few trophies with a unique design—for example, a one-of-a-kind award for an Employee of the Year or a small, personalized memento for a competition—the cost of creating a mold is completely impractical.

The 3D Printing Advantage:

Cost-Effective: 3D printing builds the object directly from a digital file, completely eliminating the need for a costly initial mold. This makes the cost of a single piece significantly lower than with traditional methods.

Unlimited Design Freedom: You can easily incorporate unique elements into each trophy, such as personalized names, company logos, specific dates, or complex character models. Each trophy can be a unique piece of art, which is incredibly difficult to achieve with conventional manufacturing.

2. When Prototyping for a Large-Volume Order

Let’s say you’re planning a large event and need hundreds or thousands of trophies, but you’re not yet sure about the final design, size, or feel. Committing to a massive production run without a physical sample is a huge risk.

The 3D Printing Advantage:

Fast and Economical Prototyping: 3D printing can quickly turn your 3D design files (like CAD drawings) into a physical model. You can rapidly create one or more prototypes to evaluate the look, verify the dimensions, and test the weight and feel.

Efficient Design Iteration: If you’re not satisfied with a prototype, you can quickly modify the 3D design file and print a new version in a matter of hours or days. This agile process helps you avoid costly mistakes after committing to mass production, saving you significant time and money.

Using 3D printing for concept validation na prototyping provides a valuable layer of security before entering a full production run.

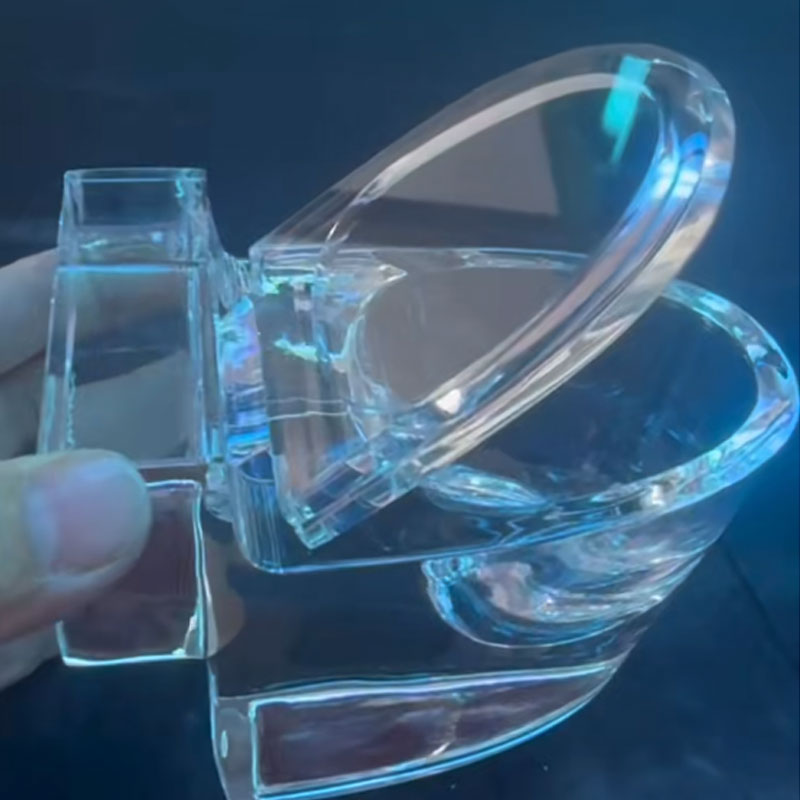

3. When Your Design Has Complex or Irregular Structures

Traditional manufacturing methods like casting or CNC machining face limitations when dealing with complex geometries. This can include internal hollows, intricate lattice structures, complex curved surfaces, or intertwined, single-piece designs—all of which can be impossible or prohibitively expensive to create traditionally.

The 3D Printing Advantage:

Breaks Design Barriers: By building objects layer by layer, 3D printing can achieve almost any complex design you can imagine. No matter how unconventional the shape or how fine the detail, if your 3D design file can render it, a 3D printer can bring it to life.

Diverse Material Options: 3D printing offers a wide range of materials, such as resin, nylon, na chuma, which give your trophies different textures and visual effects. Resin printing can create smooth, highly detailed surfaces, while metal printing provides a solid, kuhisi malipo.

If you’re looking for an award with a groundbreaking, avant-garde, or artistic design, 3D printing is the perfect way to realize your vision.

4. When Your Project is Time-Sensitive

The traditional trophy-making process—from design to molding to final production—can take weeks or even months. If your event date is approaching fast, conventional methods may not meet your timeline.

The 3D Printing Advantage:

Short Production Cycle: The entire 3D printing process is typically much faster than traditional methods. Once the design file is ready, printing can begin immediately, with production times ranging from a few hours to a few days. This allows you to easily handle urgent orders and ensure your trophies arrive on time.

Recommend

if you’re looking for a trophy that is highly customized, uniquely designed, and can be produced quickly, and if your budget doesn’t accommodate traditional molding, then a 3D printed trophy is undoubtedly your best choice.

Whether you’re crafting an exclusive honor for a single employee or rapidly prototyping a design for a large-scale event, 3D printing offers a flexible, efficient, and incredibly creative solution.