How to Make Trophies: A Step-by-Step Guide to Crafting Your Own Awards

Trophies are the ultimate symbol of achievement, celebrating success and excellence in various fields, from sports and business to academics and beyond. Whether you’re organizing an event, a competition, or a recognition ceremony, understanding how to make trophies can help you create meaningful, personalized awards for your winners.

The Trophy Making Process: Step-by-Step

Making a trophy is not just about creating a physical object—it’s about crafting a symbol that represents hard work, achievement, and recognition. Here’s a simple breakdown of the trophy-making process:

Step 1: Design the Trophy

The first step in making a trophy is to conceptualize its design. This is the most important part of the process as it sets the tone for the entire award.

Consider the Event’s Theme: The design of the trophy should reflect the nature of the event. A sports trophy may feature a traditional cup design, while a corporate award might have a more modern, sleek appearance.

Personalization: Think about how you want to personalize the trophy. Custom engraving, logos, or special features like incorporating elements related to the event can make the trophy more meaningful.

Choose Materials: Decide on the materials you will use. Common materials for trophies include crystal, glass, metal, and acrylic, each offering a different look and feel.

Step 2: Choose the Material

The material you choose for your trophy will play a significant role in its final appearance and durability. Different materials can add different aesthetics and price points to your trophies:

Crystal and Glass: Known for their elegance and transparency, crystal and glass are commonly used for high-end or luxury awards.

Metal: Trophies made from metal, such as brass, bronze, or aluminum, are durable and have a more classic look.

Acrylic: Acrylic is a more affordable option that can be easily customized with engraving and vibrant colors. It’s often used for modern-style trophies.

Wood: Wooden trophies provide a more rustic, traditional look, often used for corporate or milestone achievements.

Step 3: Mold and Cast the Trophy

After the design and material are decided, the next step is to mold and cast the trophy.

Molding Process: For custom trophies, manufacturers typically create molds based on the trophy design. This step is crucial for achieving the correct shape and size.

Casting: The selected material (metal, resin, or other) is poured into the mold and left to harden, taking the shape of the trophy. This is where the trophy starts to take form.

Step 4: Engraving and Customization

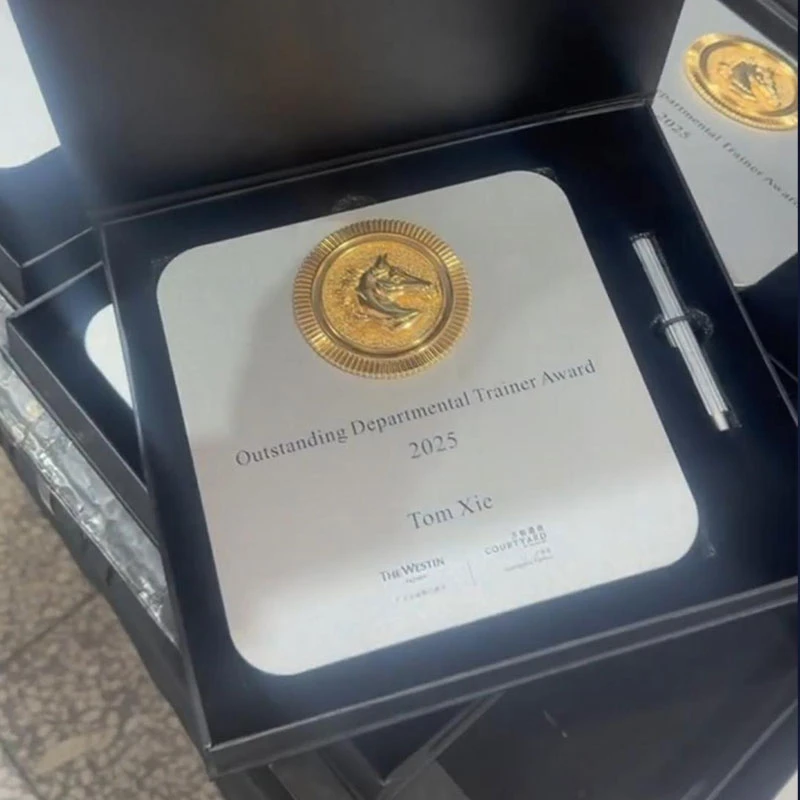

Once the trophy is cast and set, it’s time for the customization. Engraving is one of the most important steps in making a trophy, as it personalizes the award and makes it truly unique.

Engraving Names and Details: Engraving is typically done on the trophy’s surface, where the recipient’s name, event details, or special messages can be added.

Adding Logos or Designs: If you want to include a company logo or event-specific designs, this can be etched or engraved onto the trophy for a more personalized touch.

Step 5: Polishing and Finishing

Once the engraving is complete, the final step is polishing and finishing the trophy. This is where the trophy’s shine and overall appeal are enhanced.

Polishing: The trophy is carefully polished to remove any rough edges or imperfections and to bring out the luster of the material.

Finishing Touches: Additional elements, such as attaching a base or applying a protective coating, are done to ensure the trophy is both beautiful and durable.

Step 6: Packaging and Delivery

Once the trophy is finished, it’s time to package it securely for delivery. High-quality packaging protects the trophy from damage during transit. This is especially important for trophies made from delicate materials like glass and crystal.

Where to Find Quality Trophies

If you want to make trophies for an event but prefer to outsource the manufacturing process, it’s essential to work with a reputable supplier who can provide high-quality trophies that match your specifications.

One option to consider is MC ART AWARDS, a trophy manufacturer based in Shenzhen, China. MC ART AWARDS offers a wide range of customizable trophies, including options made from crystal, glass, metal, and acrylic. With years of experience in the industry, they are able to provide high-quality, personalized trophies at competitive prices. You might want to consider exploring MC ART AWARDS for your next event, as they offer excellent service and craftsmanship