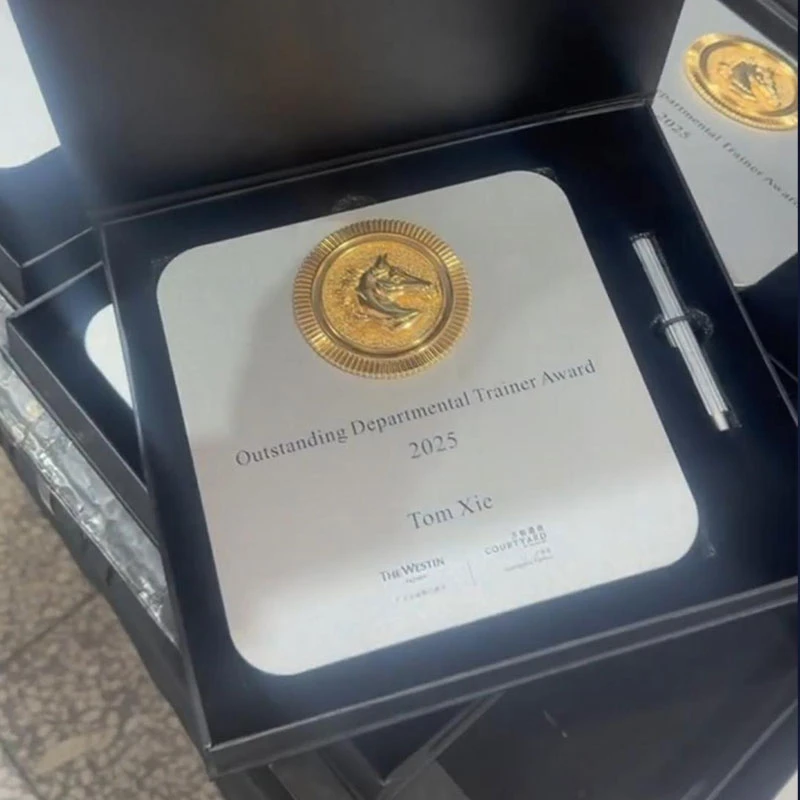

🏆 The Art of Recognition: Precision Metal Trophy Crafted with CNC and Anodizing

The act of recognition demands a symbol that is as lasting and sophisticated as the achievement itself. In the modern era of awards, the era of flimsy, mass-produced accolades is over, replaced by a demand for premium, custom-crafted pieces. The key to achieving this blend of artistry and durability lies in the marriage of advanced material science and cutting-edge manufacturing techniques.

The Superior Foundation: Aluminum Alloy and CNC Machining

The foundation of a truly exceptional award is its material. Utilizing 5052 aluminum alloy for a metal trophy provides the ideal balance of strength, light weight, and unparalleled machinability. Unlike awards created through conventional die-casting methods, which can compromise detail and surface quality, trophies crafted via Computer Numerical Control (CNC) engraving offer a superior finish.

Flawless Details: The precision of CNC machining carves intricate designs, such as the featured geometric maze pattern, with remarkable fidelity and depth. This level of detail is simply unattainable with standard molding processes.

Refined Edges: A crucial differentiator is the tactile smoothness. CNC-engraved aluminum pieces boast edges and surfaces that are finer and smoother compared to their cast counterparts, resulting in a premium feel and a cleaner, more contemporary aesthetic.

Dimensional Accuracy: For a series of awards, CNC ensures perfect consistency across the entire production run, guaranteeing that every recipient receives an identical, high-quality representation of the honor.

The Lasting Finish: The Anodized Trophy Advantage

What sets a premium aluminum award apart is its finish. The beautiful gold, silver, copper, nickel, or rose gold colors seen on these trophies are not paints or simple platings; they are achieved through the sophisticated process of anodizing.

Unrivaled Durability: Anodizing is an electrochemical process that converts the metal surface into a durable, porous oxide layer. This layer is chemically bonded to the aluminum, making it fade-proof and highly resistant to scratching, flaking, and corrosion. This ensures the award maintains its pristine appearance for generations.

Fingerprint Resistance: A common issue with polished metal is the visibility of fingerprints. High-quality anodized finishes are specifically designed to be non-stick, keeping the award looking immaculate without constant polishing.

Aesthetic Versatility: The anodizing process allows for a vibrant spectrum of colors, including the classic precious metal hues of gold, silver, and copper, as well as modern options like rose gold, all with a rich, uniform color depth.

Partnering with an Expert Trophy Manufacturer

Choosing the right partner is critical in translating a concept into a tangible, celebrated reality. The combination of 5052 aluminum, CNC engraving, and anodizing requires specialized expertise that only a dedicated, high-end trophy manufacturer can provide. The investment in superior technology and craftsmanship guarantees an award that truly reflects the prestige of the honor being bestowed.

Elevate your recognition program with an award that speaks volumes about precision, quality, and lasting value.

📞 Act Now: Design Your Ultimate Metal Trophy

Ready to create a custom aluminum trophy that perfectly symbolizes excellence? Don’t settle for less than the best in design and durability. Partner with an industry leader specializing in high-precision, anodized awards.

Contact MC ART AWARDS today to begin designing your custom CNC-engraved metal trophy!