🏆 CNC Engraving: The Art of High-Precision Metal Trophy Customization 🥇

In the pursuit of exceptional custom awards, CNC Engraving (Computer Numerical Control machining) offers unparalleled precision and detail for small-batch, high-standard metal trophy customization. If you demand the highest quality for your awards, aspiring for a product that is unique, exquisite, and flawless, CNC engraving is the ideal choice to realize your vision.

🌟 What is CNC Engraving? The Secret to “Micron-Level” Precision

CNC machining is a highly automated fabrication method. It uses computer programs to precisely control the movement of cutting tools across the metal material, achieving accurate cutting and carving of complex three-dimensional shapes.

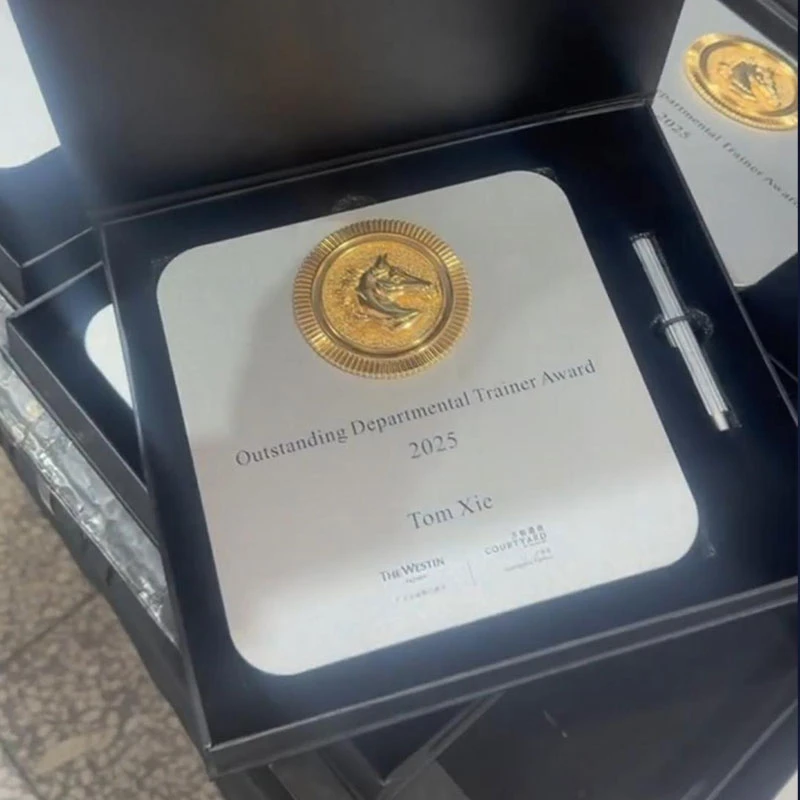

Ultra-High Precision: The outstanding advantage of CNC engraving is its astonishing accuracy. For products like metal trophies, it can easily achieve a tolerance requirement of less than $0.01 \text{ mm}$ (10 microns). This level of precision far surpasses standard manufacturing processes, allowing for the perfect realization of intricate details, sharp edges, and smooth, flowing surfaces.

Extreme Detail: Whether it’s a complex corporate logo, fine textures, or unique geometric shapes, CNC can translate every detail from the design blueprint into a tangible metal form with stunning visual and tactile quality.

Versatile Materials: It is suitable for a wide range of metal materials, including aluminum alloys, brass, and stainless steel, offering extensive possibilities for trophy design.

🎨 Why is CNC Engraving Ideal for “Small-Batch, High-Standard” Customization?

The value of CNC engraving in the customization field lies in its ultimate pursuit of quality, making it especially suitable for the following scenarios:

| Feature | CNC Engraving Advantage | Suitable Customization Needs |

| Precision & Quality | Achieves micron-level tolerances; finished surface is highly polished with perfect details. | Annual Awards, Special Commemorative Trophies, High-End Event Prizes, where craftsmanship and artistic value are paramount. |

| Flexibility | Designs can be quickly adjusted by modifying the program, without the need for mold creation. | One-off custom pieces, Designer Series, Small-batch awards with annual design iterations. |

| Material Integrity | Can directly machine solid metal stock, ensuring the trophy’s weight and substantial feel. | Clients who desire the natural metal texture and a heavy, premium feel. |

💰 Cost Consideration: Why CNC is Not Suited for Mass Production?

While the quality of CNC engraving is exceptional, the process is relatively time-consuming and relies on expensive, high-precision machinery and specialized operators, resulting in a higher cost.

Important Note: CNC engraving is primarily reserved for single or small-batch orders where quality requirements significantly outweigh cost sensitivity. If your need is for mass production (e.g., hundreds or thousands of pieces), processes like Die Casting will be a more economical and efficient choice. Die casting uses molds for rapid shaping, which drastically reduces the unit cost.

🤝 Partner with MC ART AWARDS to Craft Your Symbol of Glory!

Extreme precision demands an expert team. MC ART AWARDS specializes in high-end custom trophies, mastering the essence of CNC engraving to transform your design concepts into enduring works of metal art.

Act Now! If you require a metal trophy that represents the highest honor—perfect in detail and supreme in quality—do not settle for the mediocrity of mass production.

👉 Contact MC ART AWARDS today! Let us use the ultimate precision of CNC engraving to tailor a unique symbol of achievement for you! Click to learn more about our custom solutions and make your award stand out!