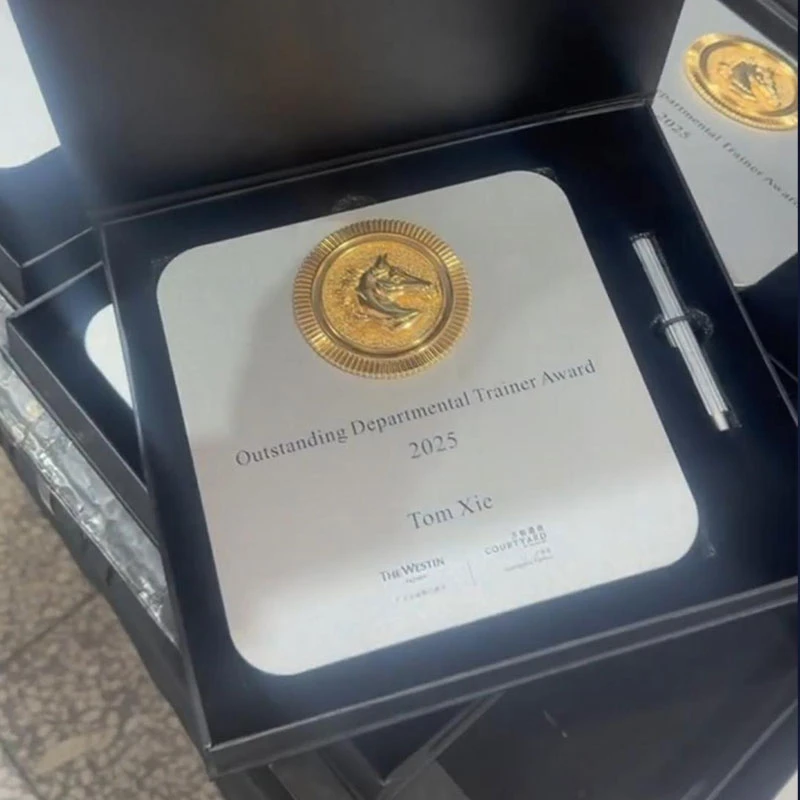

In April 2025, the Laurence Olivier Awards, the highest honor in the British theater industry, will be held at the Royal Albert Hall in London. MC ART AWARDS is the exclusive trophy for the event. This cooperation focuses on efficient craftsmanship and quality assurance, injecting the ingenuity of Made in China into this global theater festival.

Design concept:

classic shape, practicality first

The trophy design continues the iconic elements of the Oliver Awards. The main body uses the traditional silver cup shape, the top is engraved with an abstract mask pattern symbolizing theatrical art, and the base is engraved with the winner’s name and the year of the award. While retaining the classic appearance, the design team optimized the weight of the trophy to 3.2 kg, which is convenient for holding and passing at the award ceremony.

Manufacturing advantages:

the hard power of Shenzhen

factoryAs a mature manufacturing company in the Pearl River Delta region of China, MC ART AWARDS has won the favor of international event organizers with the following core advantages:

High-precision casting process

Using recyclable zinc alloy material, after 16 precision polishing and silver plating processes, the surface wear resistance is increased by 30%, which is suitable for multiple use in the award ceremony. The cup body and base adopt modular design, support fast assembly and personalized engraving services, and meet the delivery standards of batch orders.

Scaled production guarantee

Relying on the resources of more than 200 local cooperative manufacturers in Shenzhen, the full-link collaboration from mold development to mass production is realized, and the annual production capacity of a single trophy exceeds 200,000 pieces. This year’s trophy only takes 28 days from design finalization to the first batch of delivery, with an on-time delivery rate of 100%, setting a new record for the production cycle of similar orders.

Strict cost control, consistent quality

Through standardized mold development and automated processing, the cost per piece is 240% lower than similar European products, and the entire process has passed ISO 9001 quality certification. Each trophy undergoes 3 rounds of full inspection to ensure that it meets the factory standards of no bubbles and scratches.

Event Cooperation:

Experience Accumulation in the International Stage

MC ART AWARDS has continued to expand its international event trophy customization business in recent years, and has provided standardized trophy solutions for the Masters Tournament, Asian Youth Games, etc. In this cooperation, the team conducted in-depth research on the historical archives of the Oliver Award, accurately reproduced the proportions of the classic trophy in the 1960s, and added anti-slip texture design to the handle to enhance the practicality of the award ceremony.

About MC ART AWARDS

The company has been established for more than 20 years and focuses on the manufacture of trophies, medals and event peripheral products, serving customers covering global sports events, cultural celebrations and educational institutions. The Shenzhen headquarters factory covers an area of 67.98 million square meters and is equipped with a fully automatic casting production line, with annual exports accounting for 60%.