The True Cost of Design Misalignment: A Case Study in Bespoke Trophy Customization

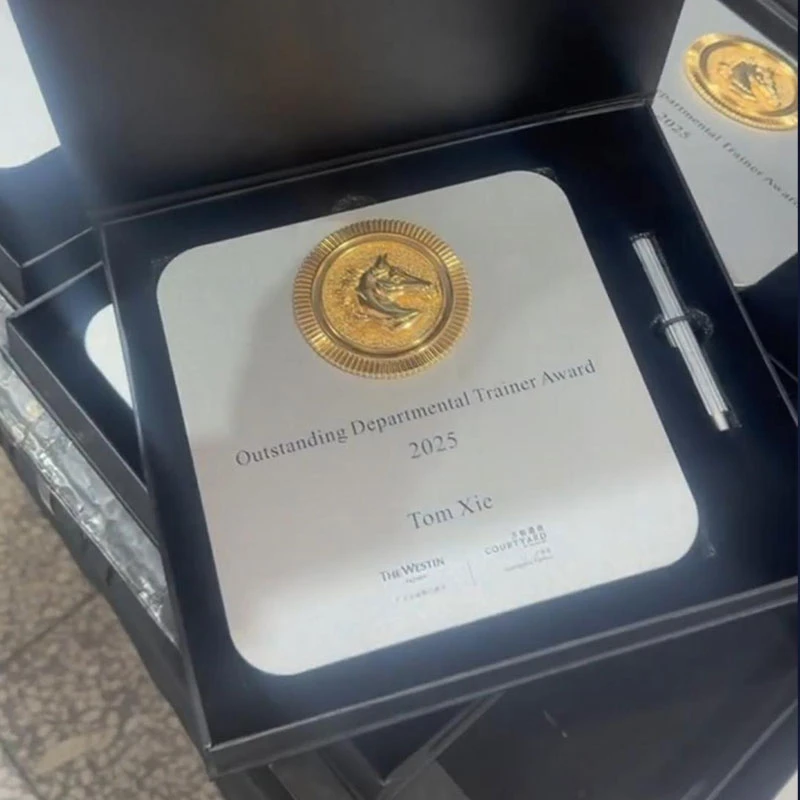

When it comes to high-end corporate recognition, precision isn’t just about the engraving—it’s about the proportions. At MC ART AWARDS, we recently completed a challenging project for a client in Dubai involving 36 custom “Recognition Awards.” This project serves as a vital lesson in the importance of trusting professional design expertise during the prototyping phase.

The Challenge: Form vs. Function

The project began with a specific request: 36 trophies featuring a metallic “R” and star emblem mounted on a crystal base. However, the client initially insisted on a square base measuring 20x20x20cm.

Our product managers immediately identified a design flaw. A base of those dimensions would appear bulky and “uncoordinated” with the sleek verticality of the “R” component. Despite our professional recommendations and warnings regarding the aesthetic balance, the client requested we proceed with their original specifications.

The Turning Point: When Reality Hits the Lens

Once the 36 trophies were manufactured to the requested specs, the visual reality set in. Upon seeing the high-resolution photos of the finished product, the client realized the proportions were indeed off. They requested an urgent change: converting the square bases into elegant rectangles.

The Risky Art of Deconstruction

By this stage, the trophies were already fully assembled using our signature high-strength industrial bonding agent. This isn’t standard glue; it is designed for permanent, crystal-clear durability.

The rework process was grueling and high-risk:

Heat Application: Using precision heat guns to melt the high-strength bond without cracking the crystal or damaging the metallic finish.

Delicate Extraction: Manually separating components where any slip could result in a total loss of the piece.

Refining & Recutting: Scraping away residual adhesive, sending the crystal bases back for professional recutting and polishing, and re-buffing the metallic “R” components.

Re-Assembly: Re-aligning and bonding the parts to meet our “Star Performer” quality standards.

The Impact: Time and Capital

Because the assembly was already complete, the rework costs reached one-third of the total order value. Beyond the financial cost, the risk of material breakage was a constant threat to the delivery timeline. Through meticulous craftsmanship, our team successfully salvaged the order, but it was a costly path to a beautiful result.

Professional Advice: Why Expert Input Matters

At MC ART AWARDS, our goal is to ensure your vision translates perfectly into a physical masterpiece. To avoid the “rework trap,” we suggest:

Trust the Proportions: If a product manager suggests a size adjustment, it is based on years of spatial design experience.

Confirm Before Assembly: Once high-strength bonding occurs, changes become invasive and expensive.

How to design your personalized trophy with aesthetically pleasing and scientifically sound proportions?

Contact MC ART AWARDS today! We provide one-on-one consultations with our product managers to offer you expert advice.